Intensive 3 Day class with both Classroom and Hands On training on the fundamentals of swaging and shaping a symmetrical sawmill bandsaw blade. Key elements include breaking down, rebuilding and adjusting hand operated swage and shape tools. Cutting edge symmetry and proper cutter bars are a major emphasis. Class also includes elements of the Sharpening and Benching skillsets required to recondition mill run bandsaw blades. The economic benefits of a well fit bandsaw are emphasized.

Currently viewing:BS-FOCUS ON FITTING SAW FILER TRAINING

Instructors use their decades of experience to present and demonstrate both conventional “manual” techniques and current state of the art “automated” techniques to restore a mill-run bandsaw blades to operational condition. Emphasis is on understanding the fundamentals of a well reconditioned bandsaw blade – cutting edge symmetry, razor sharp cutting edge, proper Level, Tension and Back, filing room productivity, and required record keeping. Courses also feature a business focused review of how a well reconditioned bandsaw blade has a positive impact on overall sawmill productivity and profitability. Lumber analysis, Filer Math and business implications of both a well put up saw and an inferior one are covered. Time saving tips our instructors have learned over their long careers are shared with our students.

Tuition includes; all required saw blades, training on both manual and automated reconditioning machinery and equipment, required hand tools, cut preventative PPE and lunch on site for each of the three days of instruction. Students take home a 3-ring binder with instructional materials from the class and links to class related on line instructional videos.

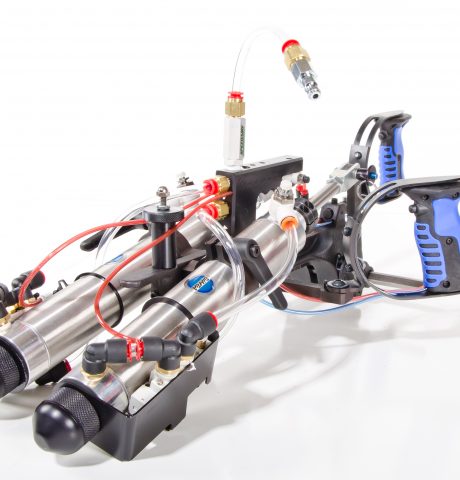

The Focus on Fitting class has students break down, reassemble and calibrate manual and air assist swage tools and manual shapers. Students also learn how the Armstrong AutoSwage operates and how adjustment technique are similar. Students swage and shape saws until they pull up the proper top cutter bar and side cutters adjusting their tools along the way. The class rounds out the training by also has students sharpen the saws and receive training on the fundamentals of benching and inspecting saws at the bench. Time is split between classroom and hands-on training with an emphasis on the latter.