Whether you are running 16″ wide doublecut sawmill blades or 1″ resaws on a multihead producing deck boards, your bandsaw blade must be properly tensioned* to cut a straight line. Too little tension and you will have wavy cuts and risk the blade coming off the mill. Too much tension and you risk shorter blade life and unnecessary wear and tear on your machine’s bearings and frame. Consult your machine OEM for the tension for your portable sawmills or pallet resaw. And then use the magnetic back Simonds digital strain gauge to hit that number time and again.

The methods that bandsaw machine manufacturers use to tension the blade can vary as much as the species sawn in our industry. What is most important is knowing the proper and optimum tension for YOUR mill and hitting that with every blade.

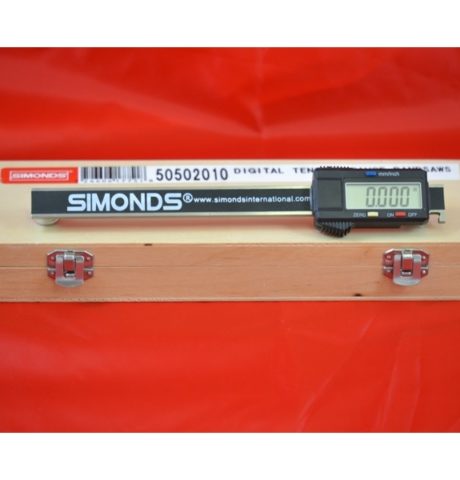

One way to calculate the tension is to measure the length the blade is stretched by the bandsaw machine. Whether a blade is a little shorter than the last one, or a little longer, if you stretch it the same distance, you will have applied the same amount of tension. Generally narrow kerf bandsaw blades should be tensioned to approximately 25,000lbs PSI. This is often a good starting point. The best way to measure that is with a Simonds magnetic back digital tension gauge. A saw stretched approximately 0.0060″, as measured with magnetic back tension gauge, will get you in that range. Most sawyers will learn where their mill operates best. Sometimes a little more, sometimes a little less.

Above is as measured with the Simonds gauge only.

*In this context, the terms Tension and Strain can be used interchangeably.