Simonds International inserted tooth slasher and cutoff saws set the industry standard for quality and are manufactured to suit a wide assortment of applications and environments.

The addition of our new Large Diameter circle saw heat treating facility in 2013 allows us to supply saws with hardness consistency and flatness on the plates we produce. Simonds only uses the highest grade nickel alloy steel to manufacture our large diameter saws. The new heat treat process allows us to produce a more robust heavier gauge saw. Our standard 2 gauge saws will provide longer run times thus reducing maintenance costs. Insist on the Simonds nickel alloy 2 gauge ITCO saw for longer run time for you and more money in your pocket!

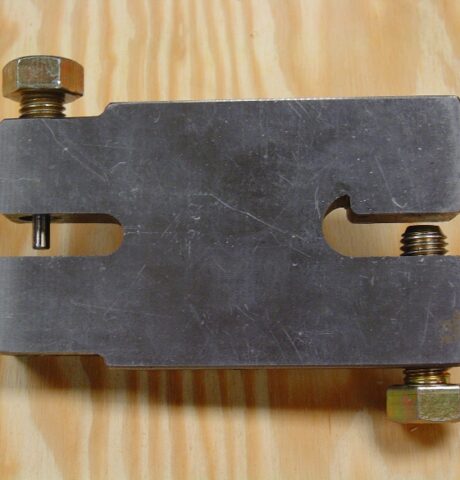

Our tough saw plates are laser cut and machined using state-of-the-art CNC equipment to ensure precise tooth-to-pocket fits. Carefully controlled manufacturing processes enable us to produce inserted tooth saws of superior quality and durability.

Our heavy duty Cut Off Saws are available with Kodiak™, F2™ or R Jumbo replaceable insert teeth. These saws can handle cutting requirements from moderate to the harshest conditions. Replaceable investment cast carbide tipped insert teeth are the proven technology to protect your high quality saw plate from damage. The proven replaceable tooth technology means maximum up time and quick tooth changes. Damaged or dull teeth can be changed on the arbor. No need to remove the saw from service to bring it back to sharp cutting condition. Inserted Carbide Tipped teeth are available with Kodiak™ .500” kerf, F2™ .475” kerf or Kodiak™ .435” kerf hollow point tips.

Simonds International Slasher Saws are available in diameters from 36″ to 96″. The most common 60″ and 72″ saws are custom finished for quick delivery from semi finished stock.