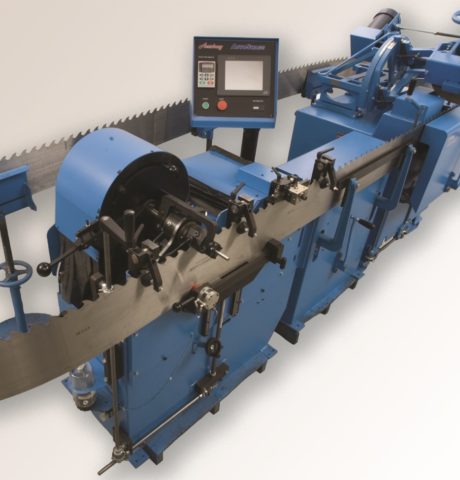

The accuracy and high quality performance you expect from Armstrong.

The world leader in band saw swaging and shaping technology for more than 100 years. The conventional eccentric die and solid carbide anvil are adjusted just like a conventional Armstrong air swage. The two carbide clamps grip the saw without twisting, for positive clamping without “swirl cuts” in the saw steel. The shaper side dies have the angles and clearance precisely ground into the carbide tips, just like Armstrong’s popular #6900 shaper to achieve the tooth you want. Even the amount of “pull down” of the tip can be adjusted quickly and precisely, making it easy to maintain a “full back” on your teeth.

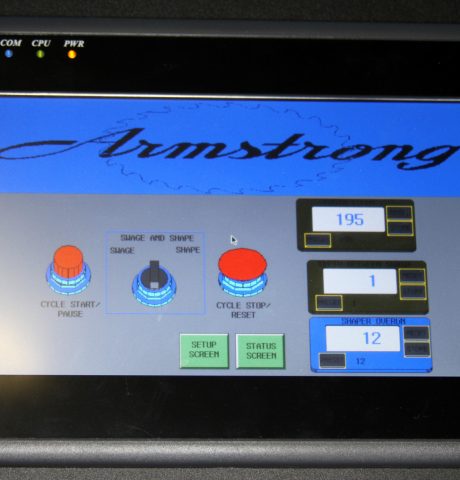

Touchscreen control and independent swaging and shaping heads for unmatched versatility.

The AutoSwage accepts saws from 4″ to 16″ wide with standard tooth spaces from 1″ to 3″. The operator can change tooth space adjustments in less than two minutes. Just pressing a button on the touchscreen changes the operation from swage only to swage & shape.

Automatic tooth face lubrication system

This system eliminates the need for an operator to apply messy oil or chalk to each tooth. Automatic shut-off stops the AutoSwage after all teeth have been accurately swaged and shaped.

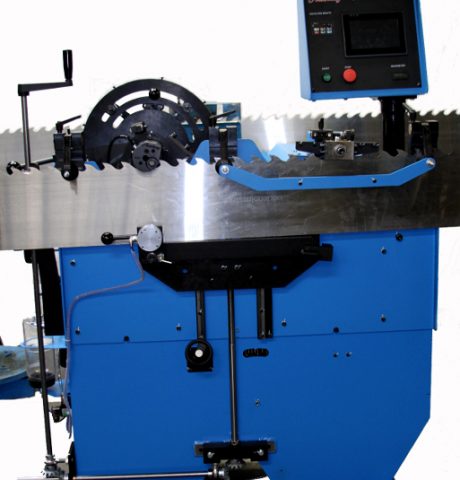

Quick change eccentric dies and swage head

This feature makes it easy to use the AutoSwage on a variety of saws. Eccentric dies in ⅜”, ½”, ⅝” and ¾” are available for the AutoSwage in the standard short bite style. The three largest size dies are also in the extra aggressive extra-short bite style, while the ½” and ⅝” sizes are also available in the mild long bite style. In all, there are nine combinations of die sizes/styles available to cover nearly every swaging situation.

Eliminate a frequent cause of repetitive stress injury while increasing productivity by automating this task.

Both filing room productivity and safety are improved.

One productive AutoSwage keeps up with four sharpeners.

Set-ups are fast – usually less than three minutes to “load and go”. The AutoSwage swages and shapes simultaneously, so a 200 tooth saw can be swaged and shaped in about 21 minutes after pressing the “start” button. Operators can accomplish other work in the file room while the saws are swaged and shaped on the Armstrong AutoSwage.

Click here to watch the AutoSwage in action!

| Armstrong’s AutoSwage Automatic Band Saw Swage and Shaper

|

|

| The Armstrong AutoSwage is available as either a right or left hand machine. Saws of the same hand as the AutoSwage encircle the AutoSwage. Saws of the opposite hand as the AutoSwage are looped in front of the machine. As shown in the illustration, one AutoSwage can swage & shape both right and left hand (or double cut) band saws by using two sets of post brackets and two air back feed units. |

|

| The Armstrong AutoSwage can be used in line with an Armstrong VariSharp or conventional #4 Armstrong band saw sharpener. The minimum saw length for using a sharpener, filing clamp and AutoSwage in line is 30 feet (saws shorter than 34 feet require that the electrical cabinet for VariSharp be placed outside the saw loop as shown in the illustration above). |

Specifications:

- Capacity: for band saws 4″ to 16″ (100 to 400 mm) wide, standard (not variable pitch) tooth spaces from 1″ to 3″ (25 to 75 mm) and saw plates from 19 to 13 gauge (1.06 to 2.41 mm).

- Power/Air Requirements: 208 – 240 volt, single phase, 60 Hz, 15 amps. Transformer supplied at extra cost for operation on 240/1/50 power. 4 cubic feet (11 liters) of air per minute at 80 PSI (5.4 bars).

- Floor Space: 46″ (1170 mm) wide x 23″ (585 mm) deep x 60″ (1525 mm) high.

- Shipping Weight: 1500 lbs. (680 Kgs)

Note: Capacities and performance subject to current design specifications at time of shipment. |

|

Features:

- Full color touch screen for easy operation in three modes: swaging only, swage & shape, or saw advance only (no swage or shape).

- Carbide anvil and reversible carbide strips in the saw carriage for low maintenance.

- Built-in lubrication system oils surface between die and tooth face for improved productivity, low machine maintenance and high quality swaging.

- Built in tooth counter shuts off swaging and shaping action after all teeth have been swaged and shaped for unattended operation.

- Fast and accurate adjustments for tooth hook angles from 15 to 35 degrees and back angles from 3 to 20 degrees allows swaging a variety of saws with minimal set-up.

- Swaging and shaping action are independently adjusted, making it easy for filers to select a light to extra-heavy shoulder on the finished swaged point.

Styles

Available |

Eccentric Die Diameter |

|

|

|

|

3/8″ |

1/2″ |

5/8″ |

3/4″ |

| Standard |

X |

X |

X |

X |

| Aggressive |

|

X |

X |

X |

| Mild |

|

X |

X |

|

Troubleshooting Guide

MANUFACTURING COMPANY

2700 SE Tacoma Street, Portland, OR 97202 USA

(503) 228-8381 Fax: (503) 228-8384

www.armstrongblue.com

Copyright Armstrong Mfg Co. 2013