Featuring:

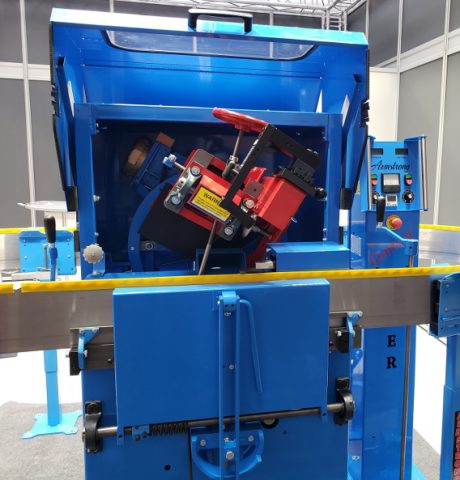

- Rugged steel and cast-iron construction

- Durability to deliver years of precision performance

- Linear Slide – Standard. Delivers more abrasive wheel diameter usage and ensures quick change over from worn wheels to new ones.

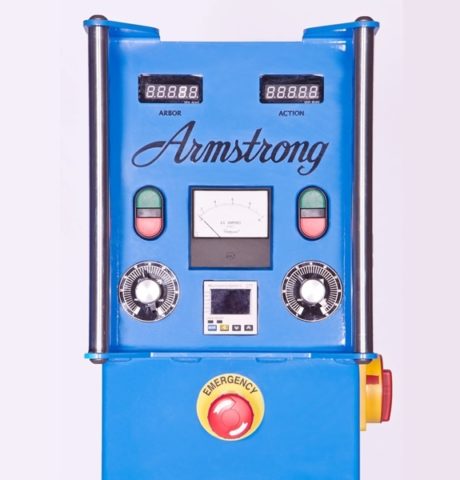

- Control Tower – Standard. Providing incredible flexibility and safety for the operation of your sharpener. Includes tooth counter for automatic shut off capability.

- Extra power for heavy sharpening. Large abrasive wheel motor (2 HP motors supplied on No. 4 sharpeners equipped for three phase current; 1 HP grinding wheel motors for No. 2 sharpeners or when single phase electrical current is specified for No. 4 sharpeners) and 1 HP action motor for heavy grinding and large saws

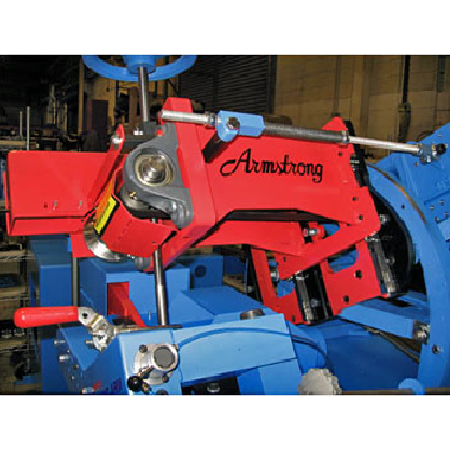

- Heavy duty abrasive wheel arbor assembly. The abrasive wheel arbor is machined from a single bar; there are no pressed joints to loosen or run out. Tapered roller bearing pillow blocks are now standard on all No. 2 Armstrong sharpeners. Poly-V belt drive to grinding wheel arbor for low vibration, no-slip grinding.

- Optional multiple, oversized UHMW cams to facilitate simple change-over from one tooth shape to another.

- Lower overall costs

- Linear Rail precision abrasive wheel head movement saves on abrasive wheels, spare parts, and saw consumption!

All Armstrong Band Saw Sharpeners come standard with:

- Linear Slide – Standard. Delivers more abrasive wheel diameter usage and ensures quick change over from worn wheels to new ones.

- Control Tower – Standard. Providing incredible flexibility and safety for the operation of your sharpener. Includes tooth counter for automatic shut off capability.

- One set of UHMW Cams – Standard. Armstrong Sharpeners are designed to use up to three pairs of cams, allowing the operator to change tooth designs simply by moving a lever and locking the camshaft into a new position. Each pair of cams is individually adjustable to enable the filer to produce a precise tooth shape.

- Safety Guards. Standard guards cover the pulley, belts and the grinding wheels, are standard on all sharpeners.

- Carbide Face Plate – Standard. The oversized, self-cleaning carbide faceplate is standard on all new band saw sharpeners. This faceplate has carbide strips set out from the steel backing plate for a wear surface that stays clean and can be reground.

- Mechanical Saw Clamp – Standard

- SwingArm Saw Clamp – Option

- StrongArm Saw Clamp – Option

- Sidewinder Feed Finger – Standard

- Revolver Feed Finger – Option

- Enhanced Grinding Wheel Arbor Assembly

- Large motors, one-piece arbor, heavy-duty pillow block bearings and non-slip, low-vibration poly-V belt drive all contribute to precision movement for extremely sharp saws and less chance of burning that can lead to cracks.

- Other options include: ShapeUp wheel dresser, Tight Loop Indicator, Safety Hood, Arbor Alignment Tool, Double Cut Saw Carriage, both manual and automatic post brackets, automatic Backfeed unit.

StrongArm II Power Clamp

The StrongArm II Air Clamp features two clamping pressures for increased grinding accuracy and extra sharp saws. The saw is clamped firmly to the carbide faceplate during face grinding while reduced pressure keeps the saw in line against the faceplate as the saw is advanced.

Swing Arm “V” Pivot Power Clamp

Dual pressure air clamp with pressure release in place of standard on a new/rebuilt sharpener or as a field upgrade kit. Literally “swings down” when grinding, and easily “swings up” to be completely out of the way for loading and unloading. Currently our most popular clamping option!

No. 75 Air Back Feed Unit

Use of an air back feed unit delivers better capacity and a smoother, more uniform feed of the saw into the sharpener. The air back feed works independently, so there is less wear and strain on the sharpener itself.

Narrow Saw Liner

For extremely narrow saw applications, Armstrong provides saw liners that act as a spacer in the saw carriage. This allows the operator to accurately grind single cut saws as narrow as 4″ wide on a No. 4 model sharpener, or 6 1/2″ wide on a No. 6 model sharpener.

SideWinder Feed Finger

The Sidewinder Feed Finger is designed for increased accuracy in profile grinding both Cobalt Chromium Alloy tipped and swaged tooth saws. The SideWinder pivots around the side of the tooth just below the Cobalt Chromium Alloy tip or swaged point, instead of over the top.

To ensure accurate grinding, the SideWinder is easily adjusted to position the feed finger square on the tooth. The swaged tooth version of the SideWinder also independently adjusts the carbide point to feed in the center of the swage pocket.

ShapeUp

ShapeUp grinding wheel dressing/ shaping/ truing system for sharper saws, and lower sharpening costs.

Safety Hoods

Safety Hoods for safer, cleaner and quieter filing rooms. All options can be supplied on brand new Armstrong sharpeners or as field upgrade kits for older Armstrong sharpeners.