Featuring:

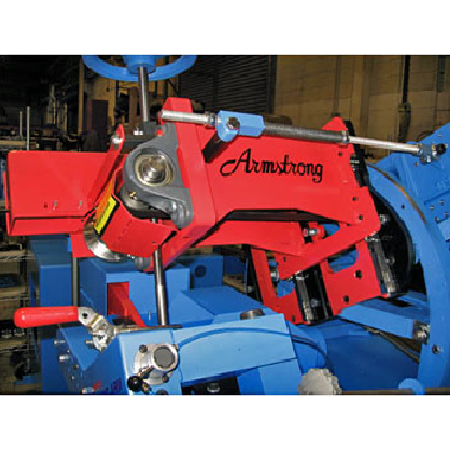

- Rugged steel and cast-iron construction

- Durability to deliver years of precision performance

- Linear Slide – Standard. Delivers more abrasive wheel diameter usage and ensures quick change over from worn wheels to new ones.

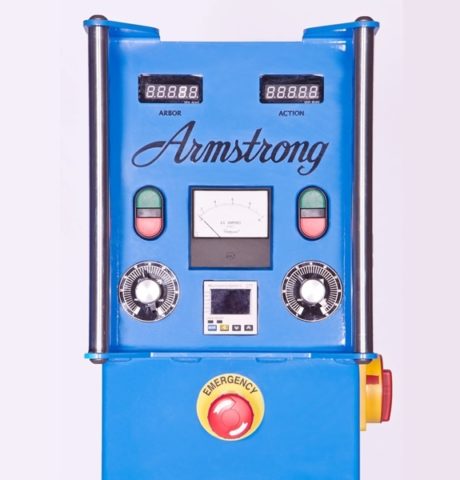

- Control Tower – Standard. Providing incredible flexibility and safety for the operation of your sharpener. Includes tooth counter for automatic shut off capability.

- Extra power for heavy sharpening. Large abrasive wheel motor (2 HP motors supplied on No. 4 sharpeners equipped for three phase current; 1 HP grinding wheel motors for No. 2 sharpeners or when single phase electrical current is specified for No. 4 sharpeners) and 1 HP action motor for heavy grinding and large saws

- Heavy duty abrasive wheel arbor assembly. The abrasive wheel arbor is machined from a single bar; there are no pressed joints to loosen or run out. Tapered roller bearing pillow blocks are now standard on all No. 2 Armstrong sharpeners. Poly-V belt drive to grinding wheel arbor for low vibration, no-slip grinding.

- Optional multiple, oversized UHMW cams to facilitate simple change-over from one tooth shape to another.

- Lower overall costs

- Linear Rail precision abrasive wheel head movement saves on abrasive wheels, spare parts, and saw consumption!

All Armstrong Band Saw Sharpeners come standard with:

- Linear Slide – Standard. Delivers more abrasive wheel diameter usage and ensures quick change over from worn wheels to new ones.

- Control Tower – Standard. Providing incredible flexibility and safety for the operation of your sharpener. Includes tooth counter for automatic shut off capability.

- One set of UHMW Cams – Standard. Armstrong Sharpeners are designed to use up to three pairs of cams, allowing the operator to change tooth designs simply by moving a lever and locking the camshaft into a new position. Each pair of cams is individually adjustable to enable the filer to produce a precise tooth shape.

- Safety Guards. Standard guards cover the pulley, belts and the grinding wheels, are standard on all sharpeners.

- Carbide Face Plate – Standard. The oversized, self-cleaning carbide faceplate is standard on all new band saw sharpeners. This faceplate has carbide strips set out from the steel backing plate for a wear surface that stays clean and can be reground.

- Mechanical Saw Clamp – Standard

- SwingArm Saw Clamp – Option

- StrongArm Saw Clamp – Option

- Sidewinder Feed Finger – Standard

- Revolver Feed Finger – Option

- Enhanced Grinding Wheel Arbor Assembly

- Large motors, one-piece arbor, heavy-duty pillow block bearings and non-slip, low-vibration poly-V belt drive all contribute to precision movement for extremely sharp saws and less chance of burning that can lead to cracks.

- Other options include: ShapeUp wheel dresser, Tight Loop Indicator, Safety Hood, Arbor Alignment Tool, Double Cut Saw Carriage, both manual and automatic post brackets, automatic Backfeed unit.