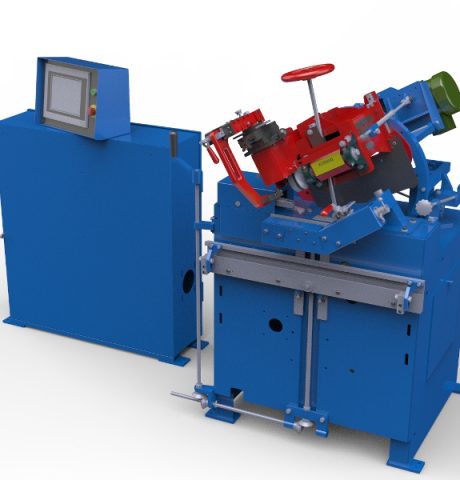

Sharpening parameters, including on/off the face, gullet depth, and number of sharpening passes can be controlled by operater inputs on the touch screen or manually as on a standard No. 4 sharpener. Abrasive wheel rpm and saw feed teeth per minute are also touch screen controlled enabling efficient stock removal and final “honing round” for super sharp saw tips. The powerful 2-hp abrasivewheel motor and variable frequency drive provide optimum sharpening performance.

The Armstrong CNC VariSharp Bandsaw Sharpener come standard with:

- VariDesign proprietary saw design software. Saw designs can be exported and shared with your sawblade manufacturer.

- Linear Slide – Standard. Delivers more abrasive wheel diameter usage and ensures quick change over from worn wheels to new ones.

- Integrated Control Tower functionality – Standard. Providing incredible flexibility and safety for the operation of your sharpener. Includes tooth counter for automatic shut off capability.

- Safety Guards. Standard guards cover the pulley, belts and the grinding wheels, are standard on all sharpeners.

- Carbide Face Plate – Standard. The oversized, self-cleaning carbide faceplate is standard on all new band saw sharpeners. This faceplate has carbide strips set out from the steel backing plate for a wear surface that stays clean and can be reground.

- Mechanical Saw Clamp – Standard

- SwingArm Saw Clamp – Option

- StrongArm Saw Clamp – Option

- Sidewinder Feed Finger – Standard

- Revolver Feed Finger – Option

- Enhanced Grinding Wheel Arbor Assembly

- Large motors, one-piece arbor, heavy-duty pillow block bearings and non-slip, low-vibration poly-V belt drive all contribute to precision movement for extremely sharp saws and less chance of burning that can lead to cracks.

- Other options include: ShapeUp wheel dresser, Tight Loop Indicator, Safety Hood, Arbor Alignment Tool, Double Cut Saw Carriage, both manual and automatic post brackets, automatic Backfeed unit.