Tip positioning on all Kirschner brazing machines is extremely accurate. The delivers to mills the opportunity to reducing sharpening times, increasing saw accuracy, and the opportunity to consider smaller kerf tips for savings.

Kirschner tippers are the most robust machines on the market requiring less maintenance while providing easiest operation.

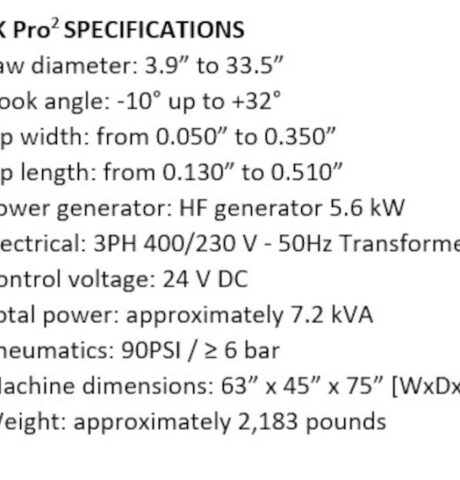

The machine delivers advanced safety and servo technology, is fast and accurate, and the Burton Mill Solution team N American based Field Service Technicians have received Factory Training on service. The machines are also incorporates aa patented no vibration sorting bowl helping create better bonds and silver melt equally behind carbide for a 15% increase of bonding strength. The bowl includes quick change over capability and no clogging. The LK Pro-2 both will braze new tips on with incredible accuracy and also remove worn tips increased efficiency.

The LK PRO-2 is available in three configurations : stand alone automatic machine, single station robot load / unload, multi cart robot load / unload.

LK Pro fully automatic brazing

LK Pro Single station robotic

LK Pro Multi Station robotic